MACHINERY & MOULD

-

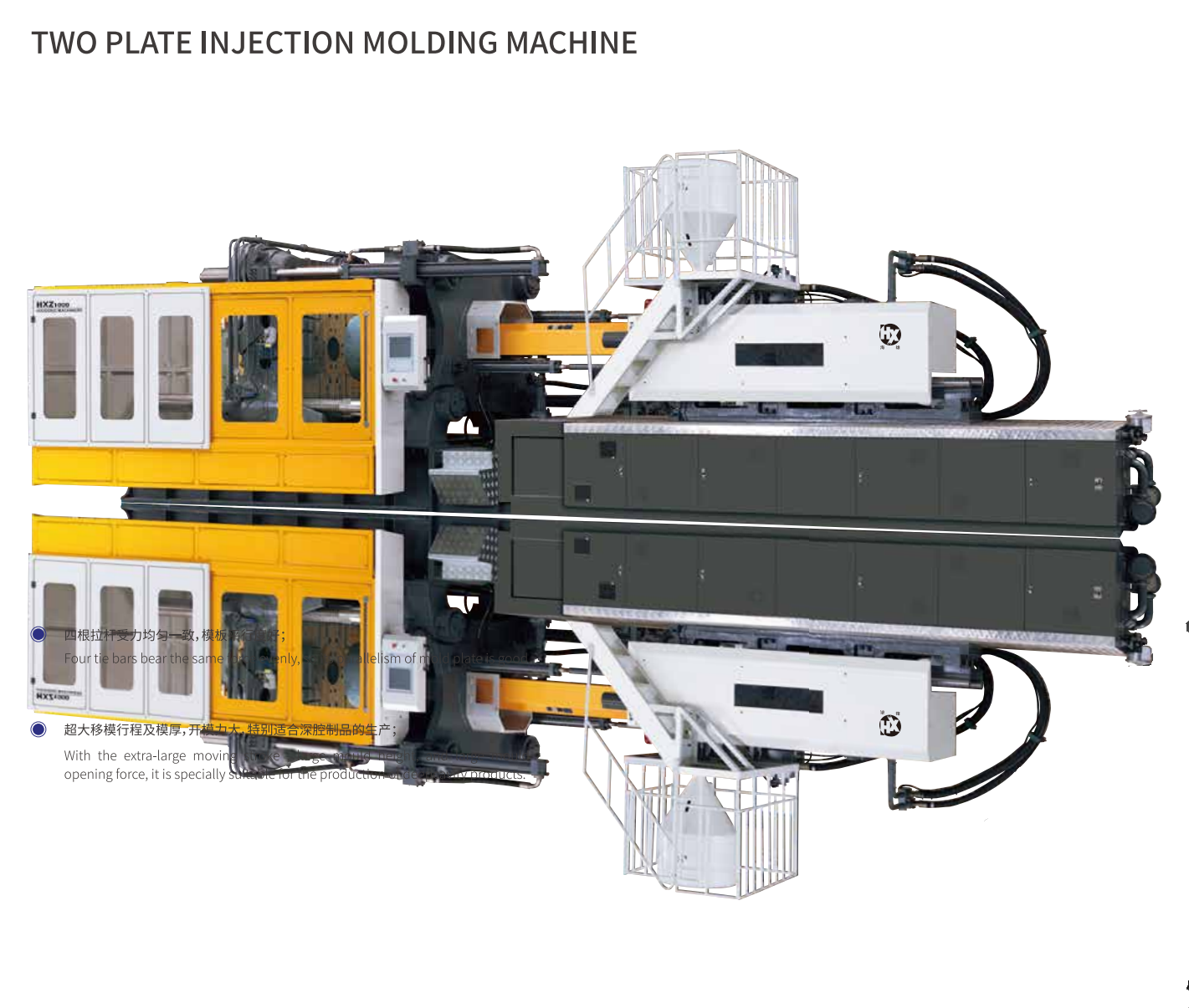

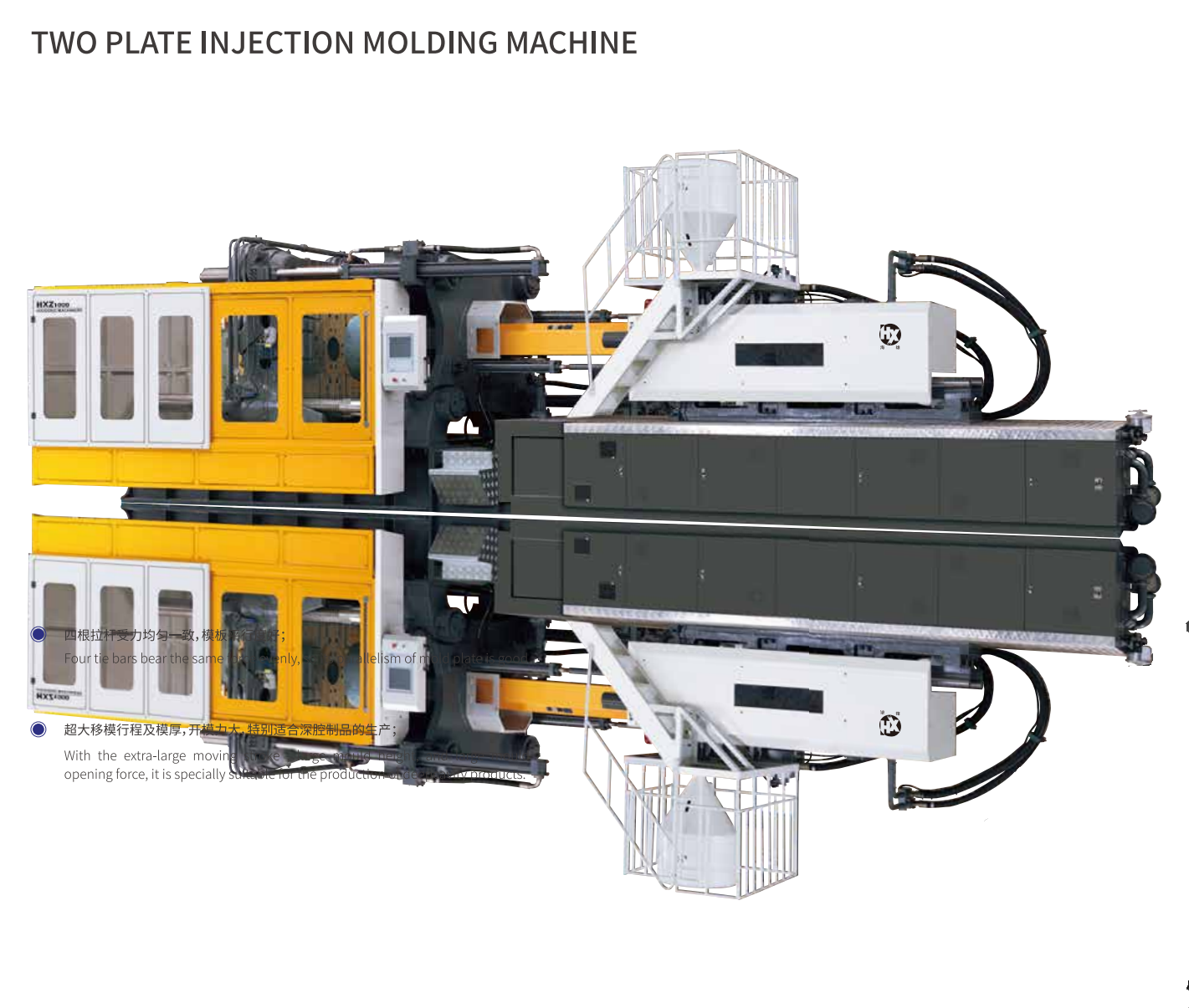

Two plate injection molding machine

Four tie bars the same force evenly.

With the extra-large moving stroke ,huge mould height,and large mould opening force,it is specially suitable for the production of deepoavity products.

The moving mould-plate adopts the long tie bars to guide direcions.It can run steadily as the distance is so long between the guide surface.

Driven by two rapid oil cylinders,the mould movements are high speed,precise and steady.The machine has short cycle time as the low pressure mold protection.¥ 0.00Buy now

-

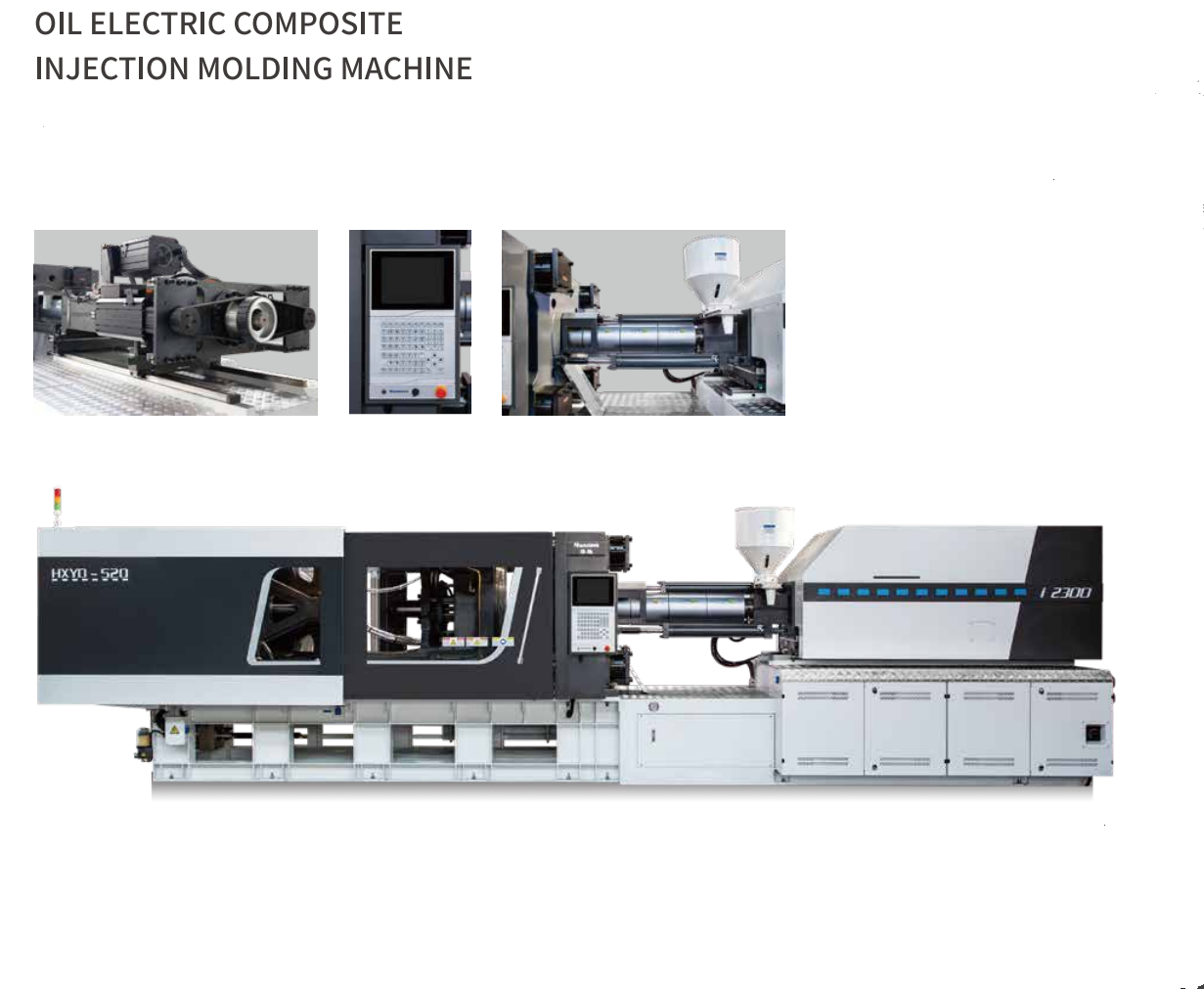

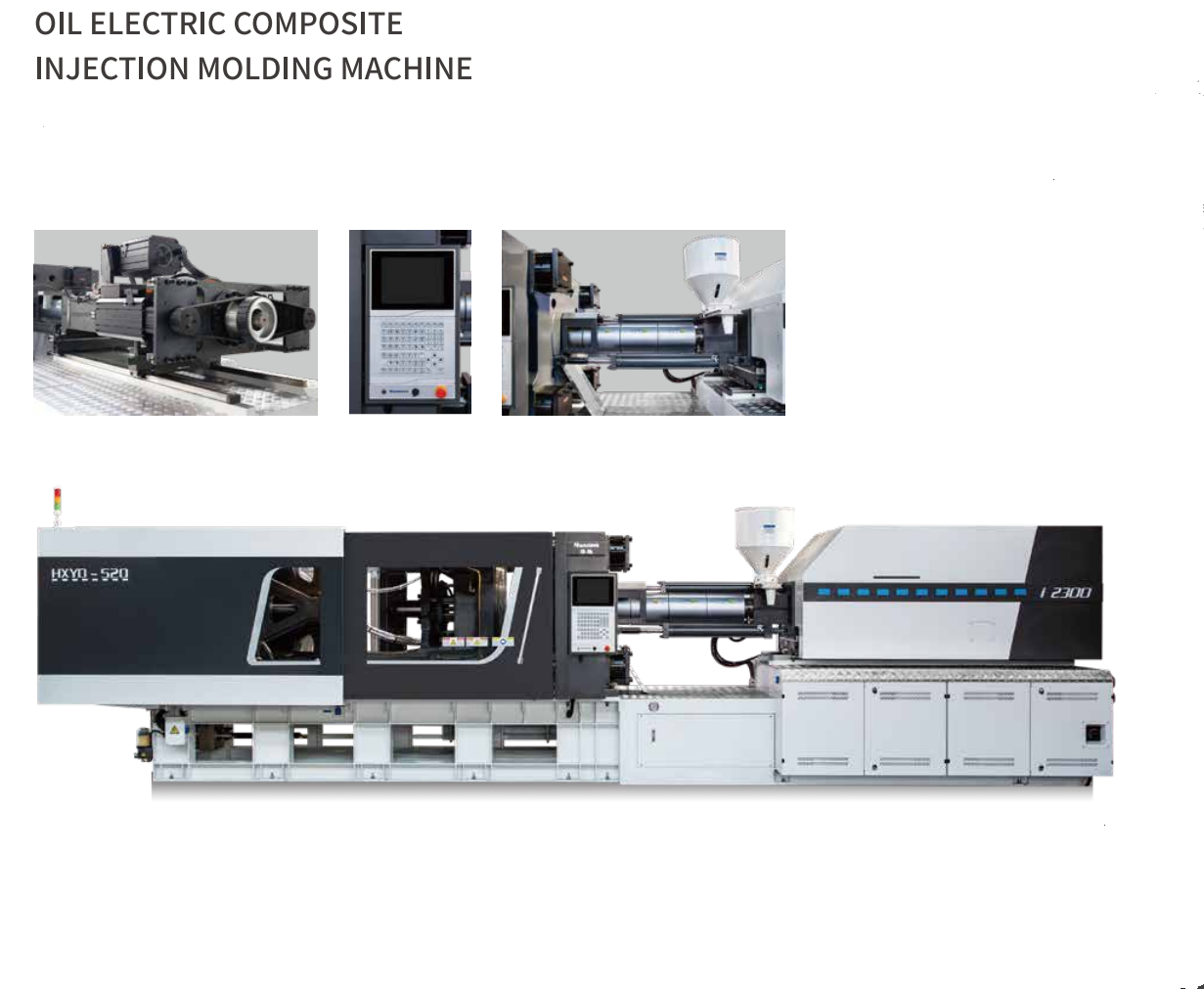

Oil electric composite injection molding machine

Close-loop control for injection,plasticizing,pressure maintaining and back-pressure.Servo motor direct drive.

Be able to do the process of feeding and opening mold at the same time,To save much more cycletime of molding.

Speed from 0 to 800mm/s need only 35 millisecond.Super high speed respond with high speed injection,accurate measurement of stroke control,it can achieve stable thin molding.

Adopt anti-interference number force transducer to achieve high precision pressure control.¥ 0.00Buy now

-

Clear TWO-COLOR Injection machine

With major and minor two injection components,can inject synchronously or alternately through the professional computer controlling two screw bars.So as get the plastic products with beautiful color

Also can manufacture the sandwich plastic products,and the cost is reduce

Can be widely used for PP/PE/PS and other raw material in two color forming¥ 0.00Buy now

-

Fruit frame special injection molding machine

Super energy saving:Ouput power varies with the load,and no energy is wasted.In the holding pressure phase,the servo motor will reduce speed,with low energy consumption;during the cool down period,the motor does not work.With zero power consumption.Compared with the ordinary injection machine,It can save 20%--80% of the power.¥ 0.00Buy now

-

PET preform injection molding machine

Super energy saving:Ouput power varies with the load,and no energy is wasted.In the holding pressure phase,the servo motor will reduce speed,with low energy consumption;during the cool down period,the motor does not work.With zero power consumption.Compared with the ordinary injection machine,It can save 20%--80% of the power.¥ 0.00Buy now

-

Servo energy-saving injection molding machine (658ton--2500ton)

Super energy saving:Ouput power varies with the load,and no energy is wasted.In the holding pressure phase,the servo motor will reduce speed,with low energy consumption;during the cool down period,the motor does not work.With zero power consumption.Compared with the ordinary injection machine,It can save 20%--80% of the power.¥ 0.00Buy now

More than 20 years of manufacturing experiences.Provide customer all the plastic machinery.

Extrusion Blow Molding Machines:For making hollow bottles,Like:Dairy bottles,shampoo bottles,detergent bottles,Lubricants bottles,Hollow Toy,Pallets,and other large plastic products.The size can be

0.1L,1L,5L,20L up to 220L.

PET Blow Molding Machine:Semi automatic,full automatic,The PET bottle can be from 300ml--20L,We can offer customers precise design for different standard machines.

The whole series Injection Machine: Two-platen injection molding machine Thin wall high speed injection molding machine Two color injection molding machine Servo energy saving injection molding

machine Specializing in PET series of injection molding machine

Auxiliary Machine:Auxiliary main machines operation,Including air compressor,Chiller,Auto loader,Mixer,Crusher,Conveyor Belt,Leak tester,Packaging machine and so on......

Capping machine:All different cap making machine

Mould:All Plastic Mould,Extrusion Blow mould,Blow Mould,Preform Mould,Cap Mould and Commodity Mould......

Please contact us

+8615867652021

E-mail: Sherry@sanezoe.com

Add: NO.100 Meilin west road,Ningbo City,Zhejiang,China